Hello Cold Chain Colleagues,

2024 is off to an incredible start, and we have already seen some fantastic accomplishments.

Our journey continues with a deep commitment to excellence and sustainability, and I’m excited to share some key highlights with you.

Our journey continues with a deep commitment to excellence and sustainability, and I’m excited to share some key highlights with you.

First, I want to extend a heartfelt congratulations to the team in McDonough, GA for winning Kellanova’s Top Gun award for the second year in a row (formerly Kellogg’s). This achievement underscores our dedication to customer service, operational excellence, and the great partnership we have with Kellanova for over 40 years.

As they have grown, we have grown. We appreciate that they foster such service focused initiatives, which drive us to continuously improve, evolve and excel. It’s through competitions like Top Gun that our team remains motivated and focused on meeting our customers’ key performance indicators.

Second, our dedication to sustainability has reached new heights with the establishment of two highly important targets. Our board has recently approved our ambitious goal to achieve 100% renewable energy by 2030, alongside our commitment to being SBTi (science based target initiatives) compliant, which means reducing 95% of our scope one and two carbon emissions by 2032.

A huge thank you to our sustainability team, led by Dan Postlewaite, with Sara Cook’s exceptional ability to translate complex sustainability topics into achievable goals. Their efforts have made it possible to develop a clear and comprehensive roadmap to reach our renewable energy goals. This plan includes a combination of energy reduction, solar arrays, green energy tariffs, and purchase power agreements for renewable energy. We are confident that these initiatives will not only lead the industry but also resonate with our customers, reinforcing our position as a sustainability leader.

In line with our ambitious sustainability journey, we are making substantial investments in modernizing our infrastructure to enhance energy efficiency. Over the next three years, we will invest $25 to $30 million in modernizing our blast freezers, expecting a 10% reduction in related power consumption. Additionally, we are incorporating AI and machine learning into our refrigeration control systems to achieve a further 10% efficiency gain overall across our network.

These improvements are critical steps toward our sustainability goals and will significantly reduce our environmental impact. We have fully vetted a green energy plan that outlines our pathway to 100% renewable power by 2030. This plan includes energy reduction, on-site solar generation, renewable energy purchase agreements, and green tariffs.

These are all significant sustainability milestones. The board, the sustainability team, and I are incredibly excited about our journey forward.

In closing, I want to reiterate how inspired I am by the dedication and impact of our Cold Crew. Each day, you prove what it means to be the Best in Cold. It’s a great time to be in the cold chain industry, and it’s an even greater time to be at USCS.

Together, we are shaping the future of cold storage with innovation, a Best in Service commitment, and sustainability at the forefront.

All the best,

Larry Alderfer | President & CEO

Going Forward – Face to Face

USCS hosts Customer Advisory Board to better listen, learn and support shippers.

They say there’s a reason we have two ears and just one mouth—it underscores the primary importance of listening. And that’s exactly why USCS values its two-year-old Customer Advisory Board (CAB).

Coming out of the nation’s COVID pandemic, USCS first formed this board to better align itself with customers’ day-to-day business realities and requirements.

USCS’s CAB involves as many as 13 different customer accounts ranging by product type, geography and size. Since CAB’s first in- person meeting in Dallas in May 2022, the group also met once—virtually—last fall. USCS hosted this year’s in-person meeting this February in Atlanta.

“We just hosted our most recent installment of CAB in Atlanta. After a tour of our McDonough II automation, our customers assembled to learn about USCS’s key initiatives, discuss the state of the industry and identify areas for collective improvement,” says Andrew Pavlicin, USCS Program Manager.

“We just hosted our most recent installment of CAB in Atlanta. After a tour of our McDonough II automation, our customers assembled to learn about USCS’s key initiatives, discuss the state of the industry and identify areas for collective improvement,” says Andrew Pavlicin, USCS Program Manager.

“At a high level, we want to generate a ‘feedback loop’ from our customer base and ensure we are meeting their needs and providing quality service,” he adds. “USCS seeks feedback from our customers to determine the CAB meeting areas of focus and our agendas likely will always change— based on what is happening in the industry and market. Ultimately, we believe that there is mutual benefit. Our expectation is that the customer also will gain insight into USCS’s strategic direction and benefit from peer-to- peer shared experiences.”

Pavlicin specifically points to five CAB objectives:

-

Capture Customer Feedback: Provide a platform where customers feel free to share direct feedback about their businesses and cold chain needs. This gives USCS better insight into their needs and preferences.

-

Build Stronger Relationships: Build stronger interpersonal relationships with customers.

-

Generate Ideas: Use CAB as a source

for new innovative ideas. Discussion can provide insight to ideas and/or programs not previously considered.

-

Market Research: Gain and share insights about customer behaviors and trends.

-

Brand Advocacy: Create positive customer experiences and build USCS’s reputation.

Representing USCS are Pavlicin as well as Mickey Hoffmann, Executive Vice President, Commercial Strategy and Development; Keith Mowery, Executive Vice President, West Region and USCS Logistics; and David Carr, Vice President, Business Development.

“CAB is a critical component of USCS’s evolving customer strategy and aims to foster long-term customer success and satisfaction,” Pavlicin concludes.

Leading – By Learning

USCS invests in critical training for tomorrow’s leaders, managers.

Although it’s true that new buildings, automation and technology generate headlines in the market, USCS also invests time and money into its most important asset—its people. This winter found the company kicking off two important employee development initiatives: a Management Skills Training Program and a Complete Leader Program.

Nicole Janeczek is Vice President of Human Resources Operations at USCS’s Camden, NJ, headquarters.

“As members of the USCS Management Team, our leaders play a critical role in our company’s success,” she says. “While our managers are ultimately responsible for the completion of work, they are the stewards of one of our most valued resources—our Cold Crew.”

She adds, “Our core commitments of Protect, Respect, Progress, Affect and Connect are the anchor of our business and serve as the guide for our company direction, our business decisions and our employees’ behavior. Our commitments are truly what set us apart from our competition. As USCS employees, it defines who we are. And as leaders, we are the most visible models of these values.”

Here are profiles of each program:

Management Skills Training Program

What: Makarios Consulting helps managers develop key principles in people management. Program goals are to help managers develop increased self-awareness, learn best-in-class management skills and apply practical tools. Participants learn to build a high performing team, give feedback, handle conflict, delegate effectively, and counsel employees to restore performance.

Who: USCS’s goal is to train as many as 540 employee-supervisors. There are typically 18 supervisors to a group and typically two groups are trained at a time.

When: USCS’s Management Skills Training Program is an intensive, four-day program. All USCS supervisors will go through the program at some point until the end of 2025. Two days of training will occur at one location and two days of training at another. Day Three and Day Four sessions likely will take place at USCS’s Camden, NJ, headquarters.

Complete Leader Program

What: With the help of Makarios Consulting, USCS offers Complete Leader Training, an advanced and comprehensive program to assist leaders in developing the vital principles of people management. It also promotes increasing self-awareness and fostering a mindset of continual growth and learning.

Who: There are 96 USCS senior level managers who will participate in this program. Groups of 18 people will go through the program at a time. The goal is to have all senior leaders participate in the program prior to the end of 2025.

When: Trainings will begin in March 2024 and will be held in two-day periods during different months, for a total of six training sessions. It will finish at the end of 2025.

To “Meat,” Exceed Expectations

USCS Quakertown West earns “The Johnsonville Way” Award

Johnsonville LLC, a leading sausage company both domestically and abroad, has many fascinating pivotal moments in its 79-year history. One of them came in the mid-1980s when owner Ralph C. Stayer dramatically reorganized the company (founded by his parents) and embraced employees as “members.” He also created “The Johnsonville Way” to define the organization’s culture going forward.

Today, the company extends The Johnsonville Way to recognize and acknowledge those suppliers who excel and support the company— just as if they were part of Johnsonville itself. Recently, USCS Quakertown, PA, West earned one of the meat processor’s coveted Johnsonville Way Awards for supply chain excellence.

As Johnsonville works with its third-party public refrigerated warehouses (including USCS McDonough II, GA), it evaluates those suppliers by truck turn-time performance, inventory accuracy and OS&D on deliveries. Johnsonville works with Quakertown West, in particular, to supply Johnsonville customers in the Northeast.

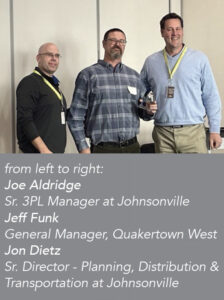

In 2023, Quakertown had 98% turn time performance for (trucks turned within two hours), 100% inventory accuracy, and 98% OS&D. Johnsonville hosted all of its third-party logistics partners at the company’s Sheboygan Falls, WI, headquarters in early December. The event included a welcome dinner, strategy updates for warehousing, transportation and marketing, a production facility tour, and even a trip to the company store. Leading the event were Johnsonville executives Joe Aldridge, Senior 3PL Manager; and Jon Dietz, Senior Director-Planning, Distribution & Transportation. Among those representing USCS at the awards dinner were Jeff Funk, Quakertown West General Manager; and Natalie Larson, Manager of Strategic Partnerships.

In 2023, Quakertown had 98% turn time performance for (trucks turned within two hours), 100% inventory accuracy, and 98% OS&D. Johnsonville hosted all of its third-party logistics partners at the company’s Sheboygan Falls, WI, headquarters in early December. The event included a welcome dinner, strategy updates for warehousing, transportation and marketing, a production facility tour, and even a trip to the company store. Leading the event were Johnsonville executives Joe Aldridge, Senior 3PL Manager; and Jon Dietz, Senior Director-Planning, Distribution & Transportation. Among those representing USCS at the awards dinner were Jeff Funk, Quakertown West General Manager; and Natalie Larson, Manager of Strategic Partnerships.

“Johnsonville values the partnership of all our providers and we view them as extended members of our team,” says Aldridge. “We accomplish this by updating them on our initiatives, sharing visibility of our business trends and educating them about our culture, The Johnsonville Way. It outlines our values and guides how we interact with our customers and providers. The Quakertown US Cold team, led by Jeff Funk, embodies The Johnsonville Way. The team is customer-focused, demands superlative performance, challenges the status quo, and helps us and our customers become great. Jeff and his team always look for solutions, partner with us to solve customer issues, and provide excellent service from turn times to OS&D results. I thank them for their dedication to our customers and our brand.”

For his part, Funk could not be more proud of Quakertown West’s performance.

“Credit for this award goes to the entire team here at the facility—all the way from check-in to check-out,” says Funk. “Every day, our Quakertown West team works very closely with both the Johnsonville warehouse transportation teams. We provide daily updates and review the Johnsonville scorecard bi-weekly. The operation team focuses on turn times for all customers but always has its eye on the Johnsonville loads.”

He adds, “This effort has successfully demonstrated continued improvement. We also take pride in shipping all loads correctly and damage free. Our CAS & Inventory teams also work daily to assure all receipts are correctly confirmed in a timely manner. Any discrepancies are immediately reported to Johnsonville with the documentation so they can update their own system without delay. The execution of these three processes are what Johnsonville recognized the team for with this award.”

He adds, “This effort has successfully demonstrated continued improvement. We also take pride in shipping all loads correctly and damage free. Our CAS & Inventory teams also work daily to assure all receipts are correctly confirmed in a timely manner. Any discrepancies are immediately reported to Johnsonville with the documentation so they can update their own system without delay. The execution of these three processes are what Johnsonville recognized the team for with this award.”

“I love working with Johnsonville,” adds Larson. “They do a great job at keeping US Cold updated with things that are affecting their business. They make a point to visit both storage locations within the USCS Network at least two times per year for in-person quarterly business reviews. The Johnsonville culture is very important and we have seen that over the years of working with them but got to see it close up after being invited to their corporate office for a great 3PL Summit.”

All for One, One for All

USCS execs lead by example in Global Cold Chain Foundation roles, activities.

It’s one thing to lead within your company.

It’s something else—and indeed, something more—when you also lead within your industry.

It’s something else—and indeed, something more—when you also lead within your industry.

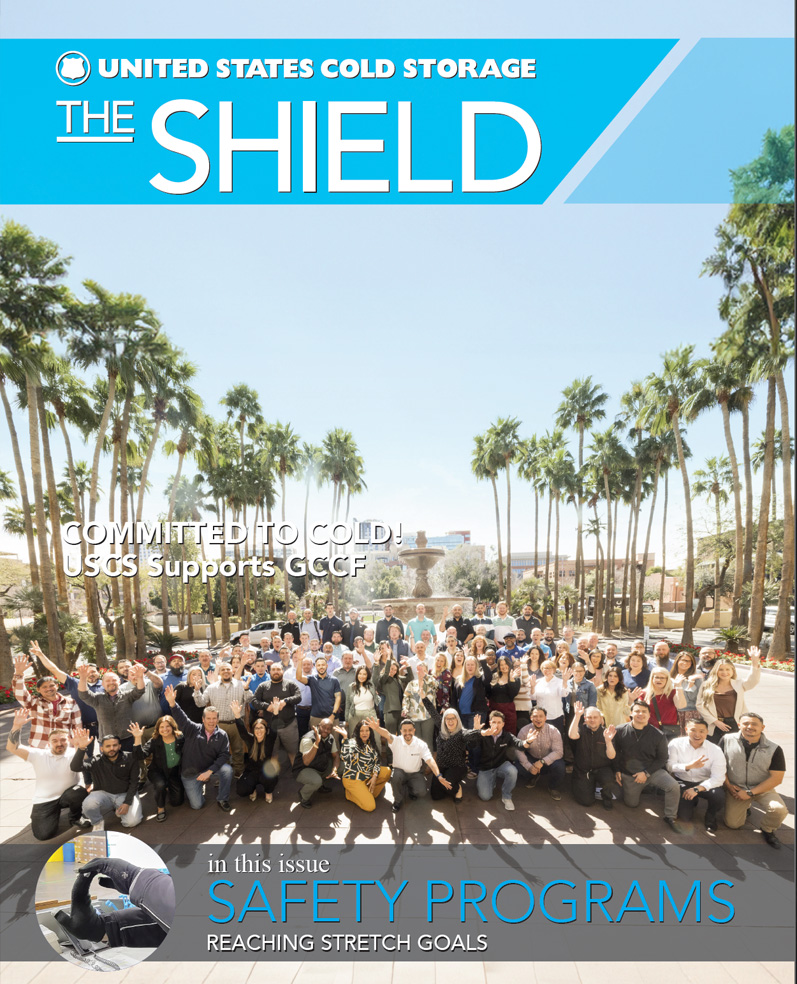

That’s exactly what United States Cold Storage is doing with executives actively stepping up at The Global Cold Chain Foundation (GCCF).

GCCF is the non-profit education, research, and international development partner of the Global Cold Chain Alliance. The Foundation’s education programs train industry practitioners in the best practices of temperature-controlled product storage, handling, and transportation. Research manuals serve as the definitive guide for the proper handling, storage, and freezing of perishable products as well as energy and facility management, and the international development projects engage cold chain industry professionals in the development of cold chain infrastructure in emerging markets.

GCCF board members elected Mickey Hoffmann, USCS Executive Vice President, Commercial Strategy and Development, as GCCF chairman for 2024. In other news, USCS West Region representatives Tamara Palefsky, Senior Regional CIT Manager, and Robert Hernandez, Area Director-North Central Valley, served with a GCCF trade mission to Southeast Asia in late 2023.

Following in the Footsteps

“I am thrilled to be named GCCF Chairman this year,” says Hoffmann. “The work of the foundation is so important to the training of the global cold chain workforce as well as advancing the development of temperature controlled best practices around the world. I look forward to working with my fellow board members to leverage the expertise of the membership to advance both those objectives.”

“I am thrilled to be named GCCF Chairman this year,” says Hoffmann. “The work of the foundation is so important to the training of the global cold chain workforce as well as advancing the development of temperature controlled best practices around the world. I look forward to working with my fellow board members to leverage the expertise of the membership to advance both those objectives.”

In an interview with The Shield, Hoffmann adds, “USCS executives have long served this association in various capacities. I’m proud to follow in the footsteps of David Harlan, Jerome Scherer and others and to continue developing the foundation as they have.”

GCCF’s Cold Chain Institute will be held in global locations (including Phoenix and Atlanta) and Hoffmann will attend several of them. He also will chair the group’s strategic board meeting this May and a regular board meeting in October.

“One goal is to conduct a holistic review of the GCCF Institute curriculum and update that program,” Hoffmann says. “I also

will encourage our members to assist in international projects that promote the cold chain around the world.”

Sharing Industry Insights

GCCA and the GCCF also work with the USDA’s “Emerging Markets Program,” which sponsored on-site visits at cold storage and logistics providers in Cambodia, Thailand, and Vietnam.

GCCA and the GCCF also work with the USDA’s “Emerging Markets Program,” which sponsored on-site visits at cold storage and logistics providers in Cambodia, Thailand, and Vietnam.

“GCCF international projects are only successful with the support of our members, who are technical experts in the cold chain,” said Madison Jaco, GCCA’s International Projects Manager. “Robert and Tamara were ideal candidates! Not only are they experienced cold chain experts, but they are also great teachers. It’s not every day that you get both.”

Hernandez led courses on food freezing and business development while Palefsky led a course on cold chain trends and technology. They also co-led a course on food safety and certifications. In addition, both USCS representatives supported on-site consultations with cold storage and logistics providers in all three countries.

“These consultations are really impactful,” said Jaco. “They allowed us to see the on- the-ground realities and make actionable recommendations for implementing new technologies and improving operations, safety, energy efficiency.”

Hernandez also reflects on the trip.

“We are still seeing the impact of these visits and trainings to this day. As I’m writing this, we already have received dozens of inquiries from the companies we’ve visited about additional best practices and commodity- specific questions. We even are planning this April to host a tour for one of those member companies. Every day, we have opportunities to impact USCS and this was even more special—to help our cold chain peers across the globe. It helped us take stock of the knowledge and experience that we have gained in our time at USCS. Likewise, it reminds us that USCS is the leader in the cold chain industry.”

>> Click here to learn more about The Global Cold Chain Foundation <<

All Systems Grow!

New optimized USCS structure will support growth, customer service and tomorrow’s leaders.

How do you react to change? The nation’s best businesses don’t fear change as an obstacle— but rather, they embrace it as opportunity.

In this case, United States Cold Storage is considering the future and optimizing its coast- to-coast organizational structure in the wake of two senior executive retirements.

Rod Noll, a 42-year company veteran and Senior Vice President-Western Region, retired at the end of 2023. Looking ahead, George Cruz, also a 42-year company veteran and Senior Vice President-Southern Region, will retire in February 2025.

“These retirement moves prompted us to reflect on the operational structure of our company,” acknowledges USCS President & CEO Larry Alderfer. “In addition, we plan to grow the company’s size by 25% during the next three to four years. It’s important that we have a robust, experienced, flexible and highly organized operational structure to absorb this new capacity and business.”

For the record, USCS offers more than 406 million cubic feet of temperature controlled warehouse and distribution space in 40 facilities located in 13 states from coast to coast. Alderfer says the company will keep four basic regions—West, Southwest, North and Southeast—but embrace a more dynamic operating structure.

“We’re moving to a more highly focused, flexible area structure. We’ll have greater management depth and flexibility to manage all of the new capacity—while we stay highly focused on service and our customers’ needs,” says Alderfer. “It also serves to move along the ongoing development of management ranks to ensure optimum succession planning over the next decade and into the future.”

The USCS optimization program includes nearly 50 appointments involving employees across nearly every one of USCS’s functional departments.

The USCS optimization program includes nearly 50 appointments involving employees across nearly every one of USCS’s functional departments.

Senior appointments include Mickey Hoffmann, Keith Mowery, and David Butterfield.

Hoffmann was named Executive Vice President, Commercial Strategy and Development and is responsible for strategy and business development with several functions, including marketing and information technology also reporting to him.

USCS promoted David Butterfield to Executive Vice President with responsibilities for the new North, Southeast and Southwest regions.

USCS promoted David Butterfield to Executive Vice President with responsibilities for the new North, Southeast and Southwest regions.

North

Steve Cunningham was promoted to Senior Vice President, North Region. His responsibilities are expanded to include warehouse operations in Pennsylvania, Virginia, Delaware, Indiana and Illinois. Other appointments include:

Tim Herm, promoted to Senior Area Director for USCS’s Quakertown East, Quakertown West, PA; Milford, DE; and Harrisonburg and Richmond, VA.

Adam Ashley, named Area Director for USCS’s Indiana and Illinois warehouse operations.

Southeast

USCS promoted Jesse Hooks to Senior Vice President with responsibilities for warehouse operations in North Carolina, Nebraska, Tennessee, Georgia and Florida.

Other appointments include:

Mike Irvin, promoted to Senior Area Director, Southeast, responsible for Georgia and Florida operations; and

Gregory Rohrbaugh, named Area Director, Central. He will oversee Tennessee and Nebraska warehouse operations.

Southwest

Senior Vice President George Cruz will manage key customer accounts and focus on USCS’s Laredo, TX, warehouses.

Other appointments include:

Carlos Stern, promoted to Senior Area Director, Southwest, responsible for warehouse operations in north Texas.

USCS promoted Keith Mowery to Executive Vice President with responsibilities for West Region operations as well as USCS Logistics.

USCS promoted Keith Mowery to Executive Vice President with responsibilities for West Region operations as well as USCS Logistics.

West

Chris Harrington, named Vice President, West Region. He is responsible for warehouse operations in California and Utah;

Chad Cox, promoted to Senior Area Director, California’s South Central Valley & Utah; and

Robert Hernandez, promoted to Area Director, California’s North Central Valley.

Logistics

In conjunction with Mowery’s appointment, USCS named two executives to new posts to optimize USCS Logistics’ structure.

Appointments include:

Mike Carlisle, named Senior Director, Logistics Operations

Wendy Snoke, named Senior Director, Logistics Services

When Every Mile Matters

Data show the dramatic sustainability impact and benefit of USCS’s COLDshare Consolidation shipping program.

More often than not, success is a matter of being at the right place at the right time. It speaks of opportunity. Then again, it’s only through the right process that a company is prepared to leverage that opportunity.

When it comes to sustainability, United States Cold Storage has embraced the right process—involving less-than-truckload consolidated shipping—for more than 50 years. USCS warehouses combine outbound, less-than-truckload orders into truckload or multi-stop truckloads. In fact, it’s now perfecting the process it calls COLDshare Consolidation (CsC). And now consider that there’s perhaps no more important time for shipper-carriers to address supply chain sustainability matters.

That speaks to USCS offering just the right solution at the right time.

“Sustainability plays a critical role in our decision making on all aspects of the business at USCS. The ability to present quantifiable sustainability metrics to our customers has been amazing,” says Mike Carlisle, Senior Director of Logistics Operations.

“Sustainability plays a critical role in our decision making on all aspects of the business at USCS. The ability to present quantifiable sustainability metrics to our customers has been amazing,” says Mike Carlisle, Senior Director of Logistics Operations.

“Most of our customers have a sustainability reporting requirement and this fulfills most of that need. It is also a great feeling when we present these metrics to a customer that is just starting their sustainability journey. It opens their eyes to what they are already doing to remove emissions from the environment.”

Carlisle notes that all USCS customers can participate in the USCS CsC program to add greater density—and benefits—for everyone. And for those customer processor-shippers estimating sustainability data for their own ESG reports, USCS analysts can help with tracking and providing that data from within USCS’s system.

“Not only are we literally driving savings for our customers, but COLDshare Consolidation has many sustainability benefits,” adds Wendy Snoke, Senior Director, Logistics Services. “We are improving truck utilization, reducing the number of trucks on the road, reducing the number of pickup and delivery appointments, reducing the number of miles travelled and reducing fuel consumption.”

Snoke says USCS first started truly quantifying COLDshare Consolidation’s sustainability metrics in January 2022. Using just last year as an example, she says USCS analysts have been able to identify true sustainability savings.

“In 2023, we found the CsC program saved more than 83,000 trucks and more than 49 million miles as a result of consolidation—as compared to all our orders shipping individually,”says Snoke. “We were able to equate that to more than 88,000 metric tons of emissions. This is equivalent to greenhouse gas emissions from 19,653 gasoline-powered passenger vehicles driven for one year. It is also equivalent to carbon sequestered by 1,460,280 tree seedlings grown for 10 years.”

To arrive at its overall sustainability impact, Snoke says USCS looked at the number of individual customer shipments delivered in 2023, versus the number of trucks that they rode on; then calculated the miles saved; and then calculated carbon emissions savings.

To arrive at its overall sustainability impact, Snoke says USCS looked at the number of individual customer shipments delivered in 2023, versus the number of trucks that they rode on; then calculated the miles saved; and then calculated carbon emissions savings.

She says USCS leverages EPA data and applies carrier-specific emissions factors to USCS’s own statistics.

“The EPA has this information for carriers that are certified through the EPA’s SmartWay program,” Snoke notes. “SmartWay carriers submit efficiency and air quality performance data to EPA annually. Therefore, when USCS utilizes a SmartWay carrier on a load we can apply a more accurate emissions factor to that load when we calculate emissions. For non-SmartWay carriers we used an average emissions factor. Once we had all of this data we were able to calculate our annual greenhouse gas emissions for CsC loads and arrive at a savings number versus individual shipments.”

Meanwhile, the calculations continue and USCS expects to refine and improve the program even more in the future.

“We’re constantly looking at ways to be more efficient and bring value to customers,” says Snoke. “During the past year, we’ve focused on maximizing efficiency in our routes by turning to data and A.I. to build better routes and support decisions. Planning smarter helps to drive miles out of the network and effectively reduce transportation related emissions.”

Meanwhile, USCS also hopes more carrier- partners join the SmartWay program.

“We encourage all of our carriers to partner with SmartWay so they can have the tools to measure, benchmark and improve operations and ultimately reduce their environmental impact,” notes Carlisle. “We will be working with all of our carriers, no matter the size, to become SmartWay compliant. We are putting together a program where we can help smaller carriers if they don’t have the ability to currently measure the requirements for SmartWay.”

To review how COLDshare Consolidation can help your company reach your Sustainability goals, complete the form below and our team will reach out to you:

Freight Consolidation

US Cold’s COLDshare Consolidation gives food producers an efficient, reliable solution.

Our consolidation services promise not just savings, but also precision in every delivery. Experience the dual benefits of financial savings and logistical precision with COLDshare Consolidation.

Innovative Technology

CsC uses SmartMove, an AI load builder making significant gains in efficiency compared to other LTL providers.

Access to Major Retailers

US Cold’s CsC has regularly scheduled appointments with the large chains in major US markets.

Streamlined Operations

Optimize your operations and maximize productivity with our solutions tailored to your specific needs.

Cost-Efficient Solutions

Reduce expenses and increase profitability with our cost-effective strategies and services.

Carrier Management

Quality control and ongoing qualification programs ensure you use top-rated drivers.

Scalable Solutions

Grow your business confidently with solutions that scale seamlessly to accommodate your evolving needs.

Reliability and Consistency

Rely on our dependable services and consistent performance to meet your logistical demands.

Customization and Flexibility

Tailor-made solutions that adapt to your unique requirements, offering flexibility and agility in every aspect of your operations.

Sustainability Focus

Embrace sustainability and environmental responsibility with eco-friendly practices and solutions that reduce your carbon footprint.

Nationwide Reach, Local Expertise

We offer coast-to-coast consolidation solution while catering to your specific regional requirements.

To redefine your shipping strategy for the better, complete the form below and our team will reach out to you:

Teamwork Makes the Dream Work

USCS sets low injury rate record in 2023, eyes more gains this year.

USCS sets low injury rate record in 2023, eyes more gains this year.

The performance of a company’s daily operations rarely generate headlines. However, at year’s end, the impact of so many small, hour-to-hour achievements is undeniable.

For starters, USCS posted record low injury rates last year, according to Lisa Battino, CSP, Vice President of Compliance & Safety.

“Our teamwork in 2023 launched our safety program to new heights and resulted in record performance across the board,” she says. “Thanks to everyone for their contributions and commitment.”

“Our teamwork in 2023 launched our safety program to new heights and resulted in record performance across the board,” she says. “Thanks to everyone for their contributions and commitment.”

Actually, that turned out to be just one of six noteworthy achievements. Battino credits the company’s Cold Crew for updating its “Management of Change” program and instituting a “Train the Trainer” class for protecting against falls. Last year also saw USCS test several new safety technologies, complete an annual crisis management drill and begin a five-year revalidation program of Process Hazard Analysis.

Battino has even more accolades to share.

“Our annual Innovators Grand Prix continues to show engagement and success throughout the sites. Congrats to our first, second and third place winners—who respectively were Minooka, Warsaw, and Tulare South. In other news, we took a ‘back-to-basics’ approach to training and our Safety Leader team reviewed every USCS facility’s training program to focus on its content and documentation. We also started transitioning our new employee safety training to a new learning management system within our UKG corporate human resources platform.”

Forward to the Future

For that matter, Battino has just as many goals and activities scheduled for this new year.

“In 2024, our goal is to reduce injury rates by another 2.5% and continue the downward trend towards our ultimate goal of zero lost- time injuries,” she says.

This year will see USCS create a trainer performance feedback program to help all safety trainers. The company also plans to host its third Safety Summit this August in Denver, CO.

“In particular, we will continue to focus on new employee safety training,” Battino notes. “We’ll utilize our updated HR learning management system to administer and track training. We realize that new employee training is a key part of our safety program and helps set the expectations that our Cold Crew’s safety is crucial to our success.”

Growing Region, Growing Company

Expansion to make USCS Tulare North, CA, site the company’s largest single facility.

“I am thrilled for our fifth strategic expansion in Tulare,” says Chris Harrington, USCS Vice President, Western Region. “This expansion reflects the continued growth of some of our major customers who are broadening their manufacturing capabilities.

“I am thrilled for our fifth strategic expansion in Tulare,” says Chris Harrington, USCS Vice President, Western Region. “This expansion reflects the continued growth of some of our major customers who are broadening their manufacturing capabilities.